Manufacturing

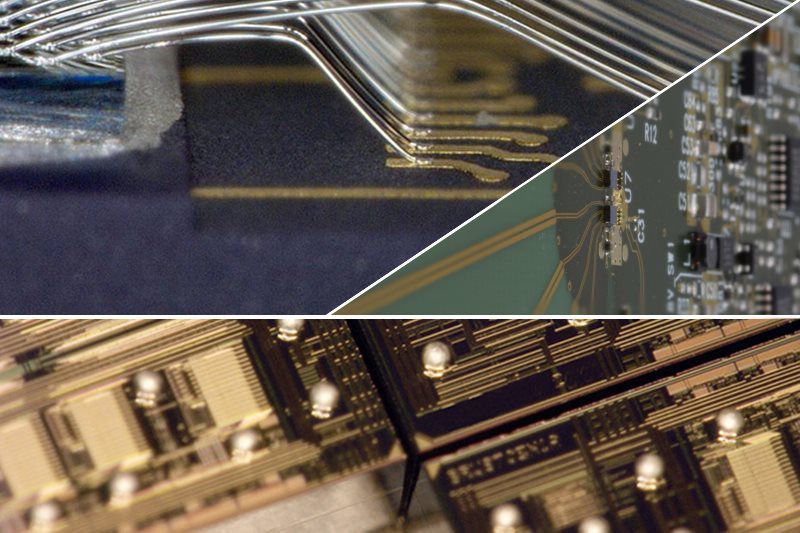

AEMtec for Assembly of Complex Optoelectronics Modules

Integrating optical components with smart electronic systems requires not just the use of high tech manufacturing equipment to produce product but it requires great know-how and skill to use the required equipment.

With over 25-years experience in the field of optoelectronics and a network of highly experienced partners, AEMtec offers Comprehensive expertise along the entire value chain including the design of optical components systems all the way through microsystem integration.

Electronics

- State of the art and cutting edge assembly techniques

- Advanced Packaging (Flip Chip, COB, SMD)

- High precision placement

- In-house test engineering group

- Fully automated wafer dicing

Optics

- Active automated alignment of optoelectronic modules

- Development and maintenance of customized tools

- Assembly of precision optics in complex mechanical modules

- Assembly in clean room class down to ISO-5 (class 100)

Mechanics

- Mechanical assembly with high standards regarding planarity and parallelism

- Precise mechanical alignment (sub-micron accuracy)

- Tolerance compensating gluing with defined layer thickness

- In-house CAD design of mechanics

- Incoming inspection of material with high accuracy, automated 3D measurement systems

Services

- Package Technology

- Life Time Testing

- Thermal Mechanical Simulation

- (Finite Element Method FEM)

- Industrialization

Volume Supply

- Worldwide deliveries

- All common logistic models

- Complete Supply Chain Management

For more information click on the AEMtec logo at the top of the page.

Sample Technologies

- 64 x 64 VCSEL’s

- Lens array to focus beams glued with UV glue

- Glass substrate with 2 alignment marks at each VCSEL's position

- VCSEL's dimensions 0.2 x 0.2 x 0.15mm3